We have been developing bicycle parking systems since 2010. Based on the experiences of our customers, our Research & Development staff constantly works to improve bicycle parking on our three main criteria:

- Durability – ensure a long lifespan with minimal maintenance requirements.

- Customer experience – provide cyclists with the most convenient parking solution.

- Efficiency – increase the number of parking spots per square meter.

2-level parking system

In 2011, this resulted in the development of our unique two-level parking systems. By introducing Lifting Pillars, no heavy physical lifting was required anymore to place bicycles on the higher level. In the same year, our Sliding Racks made it easier for cyclists to park their bicycles on the ground level by drastically reducing the problems with tangled steering handles and baskets.

Together, these improvements made sure that we now accommodate more than 50 bicycles per stretch of 10 meters while improving convenience for cyclists. More than any other bicycle parking system.

Read on for some more examples of our continuous innovation in Bicycle Parking systems.

Heavier bikes

Electrical bikes did not only make it easier for cyclists to get around but they also allowed for the design of heavier bicycles, sometimes with wider tires.

Our new Sliding Racks can now be ordered for tires up to 70mm wide and for weights of up to 50kg (most electric bicycles weigh 20 to 28 kg).

Look at our article on Heavier Bikes for more information.

Piston-driven Lifting Pillars

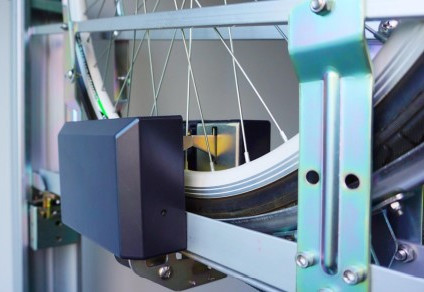

More important was the introduction of Bike Parking 2.0 in 2015. In our original design, the lifting for the second level was done by a coil spring. However, in rare situations fingers of users got stuck behind the spring while in addition, the coil springs started to deteriorate after4.000 to 8.000 times of use with a few incidents of springs that broke while being used.

For this reason, we developed completely new and encased Lifting Pillars that work with gas springs (pistons). Not only are pistons more durable, but by encasing the actual piston, users can no longer touch or reach the empowering mechanism with their hands. In addition gas springs provide a more stable, continuous, rise as compared with the fast rise that is created with coil systems.

In the video below you can see the difference between the old coil spring-based system and the new piston-based system.

All systems in this video are designed and manufactured by us.

The decision to completely encase the lifting system was a good one as we have had no maintenance issues since the installation of this new design and due to our patented approach, we are the only manufacturer providing this innovative, durable and safe design.

QR-Code Locking & Charging system

Designed for the unmanned operation of paid parking lots, locking and unlocking takes place by scanning a QR-code and can be combined with online payment processing.

Smart Cities

Smart sensors can now be connected to our cloud system provide real-time information on usage.

This allows cyclists to see where in a city parking is available while utilization graphs show managers the usage per location and even per bicycle rack.

These are all examples of how our consultants and our R&D Team constantly work together to meet the parking requirements of cities, schools, sport locations, companies while providing more comfort and more easy-of-use to the actual cyclists.

Do you want to benefit from innovation in bike parking systems? See how Bike Parking 2.0 will fit at your location? Then contact our team and give them your dimensions. We look forward to showing you what you can do with Bike Parking 2.0.